Full Life Cycle Specialization Package Service

Full Life Cycle Specialization Package Service

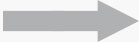

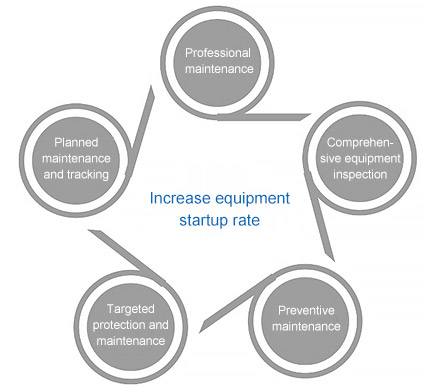

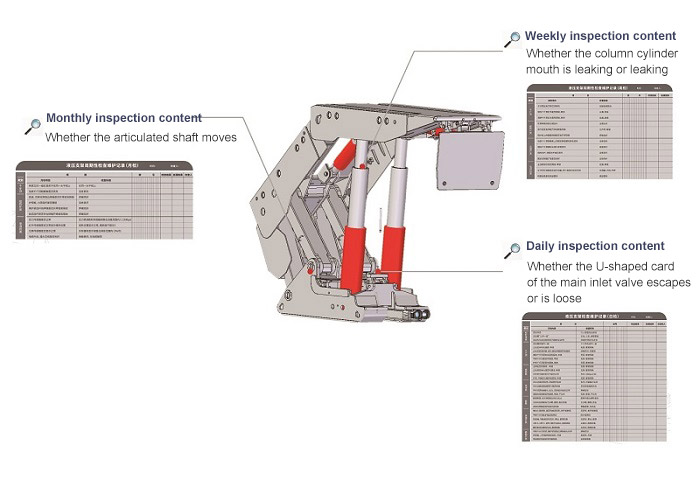

Routine inspection: Routine daily, weekly, monthly routine inspections, timely repairs, and eliminate hidden troubles.

Preventive maintenance: Through routine statistical analysis, formulate preventive measures to reduce the sudden failure rate of equipment and prevent equipment from becoming overworked.

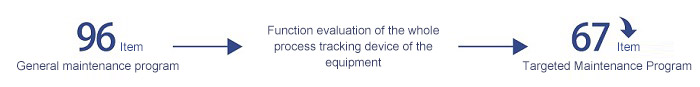

Planned maintenance: The daily inspection and maintenance data, equipment operation and other data are analyzed and analyzed through a professional information management system for daily inspection and maintenance data to trigger and implement planned maintenance.

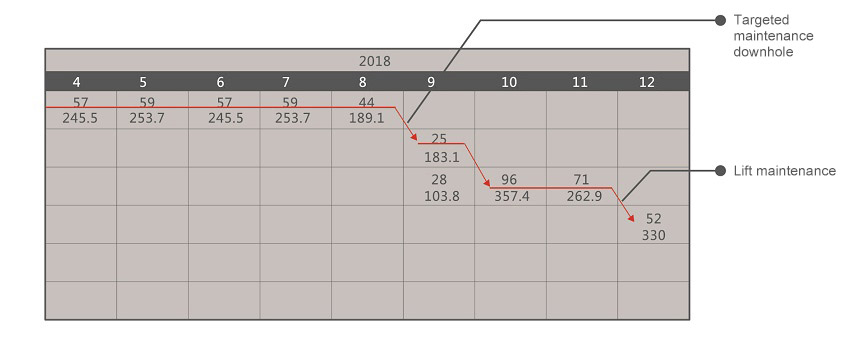

Targeted maintenance: According to the actual production continuation table and the use status of each component of the equipment, the maintenance period is planned and the maintenance plan is implemented.

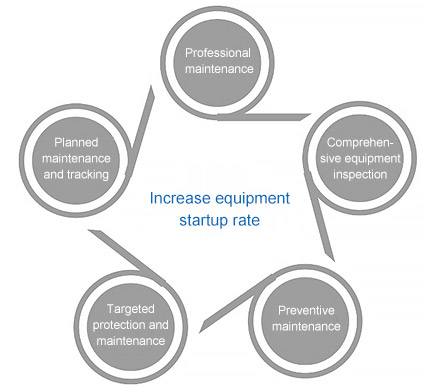

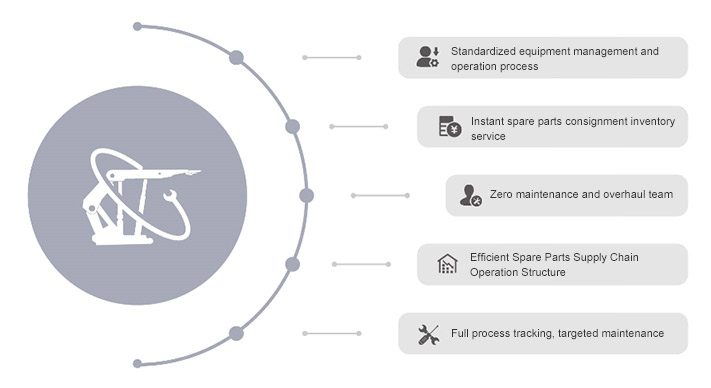

Maintenance ability guarantee: Professional service team personnel have engaged in hydraulic support work for more than 5 years accounted for 90%, 100% hold special types of underground operations guarantee, and have high-quality professional skills, can quickly go to mine independently The customer deals with the problem.

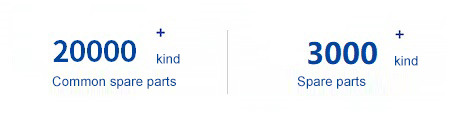

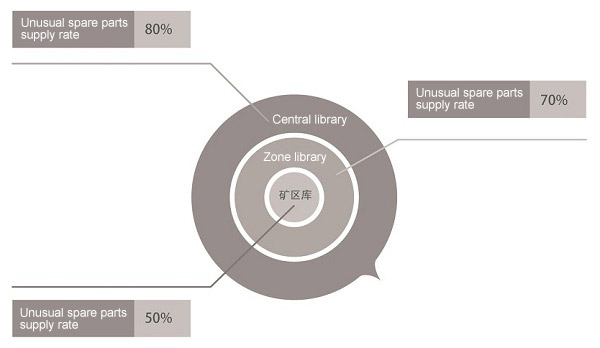

Spare parts supply guarantee: According to project characteristics and equipment use phase characteristics, hierarchical storage and deployment, periodically optimize the storage structure, and quickly meet the project's daily maintenance, preventive maintenance, planned maintenance and other spare parts use requirements.

The company commonly stocks more than 20,000 types of spare parts, and more than 3,000 types of spare parts.

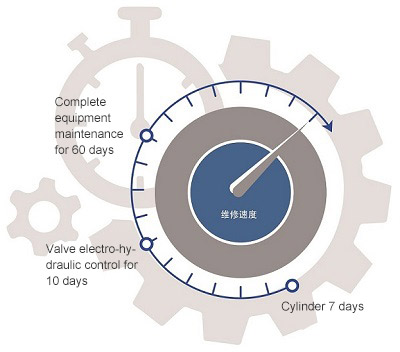

Maintenance support:In the service area, we set up specialized repair outlets for core components such as oil cylinders to quickly respond to equipment maintenance needs. We can achieve 7 days for oil cylinders, 10 days for valves and electro-hydraulic controls, and 60 days for complete equipment maintenance to ensure continuous equipment operation.